Rod Molybdenum Maʻemaʻe, Bar Molybdenum, Electrode Molybdenum

Nā kikoʻī

ʻAno a me ka nui:

| ʻAno | Nā Koʻokoʻo Swaged | ʻO nā lāʻau pololei ma hope o ka huki ʻana | Loaʻa nā koʻokoʻo lepo a mīkini paha |

| Nui | Ф2.4~120mm | Ф0.8~3.2mm |

Huina Kemika:

| Mo Maʻiʻo | Huina o na mea e ae | ʻO kēlā me kēia Element Content |

| ≥99.95% | ≤0.05% | ≤0.01% |

Nā noi

- He kūpono no ka hana ʻana i nā ʻāpana implantation ion.

- No ka hana ʻana i nā ʻāpana kumu kukui uila a me nā ʻāpana vacuum uila.

- No ka hana ʻana i nā mea hoʻomehana a me nā ʻāpana refractory i nā umu wela wela.

- Hoʻohana ʻia i ka ʻoihana aniani a me ke aniani fiber, hiki ke mālama i ke ola lōʻihi i ka wai aniani hoʻoheheʻe ma 1300 ℃.

- Hoʻohana ʻia e like me nā electrodes i ke kahua o ka ʻoihana metala honua.

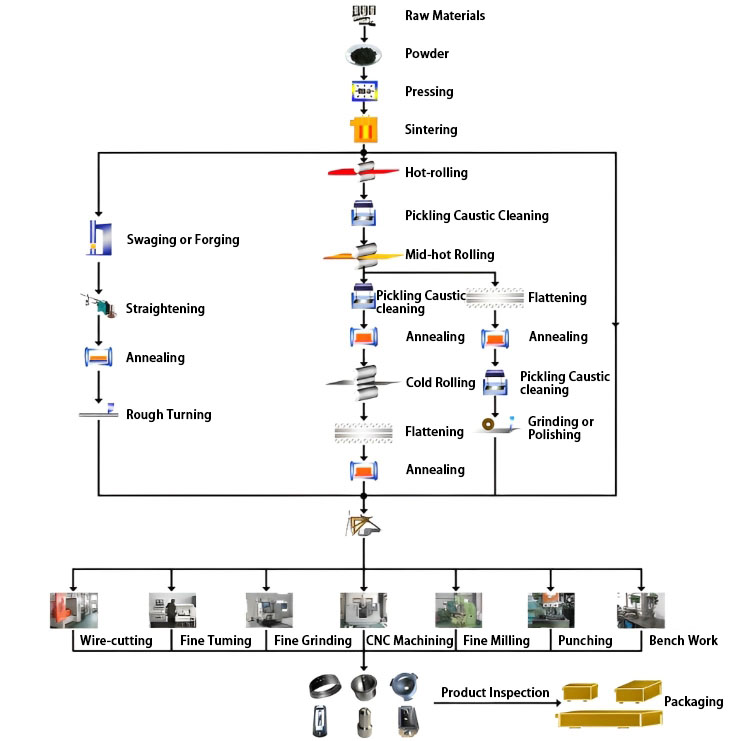

Ka hana hana lima

Mea Maka:E hoʻomaka ana mai nā mea waiwai, koho mākou i nā mea waiwai kiʻekiʻe, kahi i koʻikoʻi i ka paʻa a me ke kūlike o nā huahana.E ʻike i nā ʻano like ʻole o nā mea maka a e kaha i ka helu pūʻulu.A e hōʻike ʻia kēlā me kēia pūʻulu o nā mea maka, nānā ʻia a mālama ʻia.E hōʻoia i ka traceability o kēlā me kēia huahana i hoʻopau ʻia a hoʻomaikaʻi mau i ka maikaʻi o ka huahana.

Pauka:ʻO ka mana o ke kaʻina hana wili o nā huahana Zhaolinxin Metal he pololei loa, me nā mea hui nui a me nā vibration platform e hōʻoia i nā mea i loko o ka pulverizing a me ka hui ʻana i hiki ke hoʻoulu ʻia a hoʻokaʻawale ʻia, i mea e hōʻoia ai i ka hoʻonohonoho ʻana o ka hui kūloko o ka. huahana.

Ke kaomi nei:I ke kaʻina hana o ka pauka compacting, kaomi ʻia ka pauka e nā mea paʻi isostatic e hana i kona ʻano kūloko a me ka paʻa.Loaʻa iā Zhaolixin i nā ʻāpana ʻāpana maikaʻi loa, a loaʻa pū kekahi i nā lako hana isostatic e hoʻokō ai i ka hana ʻana o nā pūʻulu ultra-nui o nā huahana.

Sintering:I ka pauka metallurgy, ma hope o ka hoʻokumu ʻia ʻana o ka pauka metala e ke kaomi isostatic, ua wela ia ma kahi mahana haʻahaʻa ma mua o ka hoʻoheheʻe ʻana o nā mea nui e hoʻopili ai i nā ʻāpana, i mea e hoʻomaikaʻi ai i ka hana o nā huahana, i kapa ʻia ʻo sintering.Ma hope o ka hoʻokumu ʻia ʻana o ka pauka, ʻo ke kino paʻa i loaʻa ma ka sintering he ʻano mea polycrystalline.Hoʻopili pololei ke kaʻina hana sintering i ka nui o ka palaoa, ka nui o ka pore a me ke ʻano palena o ka palaoa a me ka hāʻawi ʻana i ka microstructure, ʻo ia ke kaʻina kumu o ka pauka metallurgy.

Ke kalai ʻana:Hiki i ke kaʻina hana forging ke loaʻa i ka mea kiʻekiʻe kiʻekiʻe, ʻoi aku ka maikaʻi o nā waiwai mechanical, a pāʻani i ka hoʻoikaika ʻana i ka ʻili.ʻO ka mana kūpono o ka wikiwiki o ka hana a me ka hoʻoulu ʻana i ka mahana o ka tungsten a me nā mea molybdenum he mea koʻikoʻi no ka hana kiʻekiʻe o Zhaolixin tungsten a me nā mea molybdenum.ʻO ke kaʻina hana o ka hoʻohana ʻana i ka mīkini forging no ka hoʻopili ʻana i ke kaomi i ka blank metala e hoʻololi i ka plastically no ka loaʻa ʻana o ka forging me kekahi mau waiwai mechanical, kekahi ʻano a me ka nui.

Kaʻa ʻana:ʻO ke kaʻina ʻolokaʻa e hana i ka mea metala i ka deformation plastik mau ma lalo o ke kaomi o ka ʻōwili ʻōwili, a loaʻa i ke ʻano o ka pauku a me nā waiwai.Me ka tungsten kiʻekiʻe a me ka molybdenum anuanu a me ka ʻenehana ʻōwili wela a me nā mea hana, mai ka tungsten a me ka molybdenum metala blank a hiki i ka hana ʻana o ka tungsten a me ka molybdenum foil, Zhaolixinguarantees iā ʻoe i ka ʻenehana hana kiʻekiʻe a me nā waiwai metala kiʻekiʻe.

Hana wela:Ma hope o ke kaʻina hana forging a me ka ʻōwili ʻana, ua kau ʻia ka mea i ke kaʻina hana wela e hoʻopau loa i ke koʻikoʻi kūloko kūloko o ka mea, hāʻawi i ka pāʻani i ka hana waiwai, a hoʻolilo i ka mea maʻalahi no ka machining ma hope.Loaʻa iā Zhaolixin nā kapuaʻi kapuaʻi a me nā kapuahi hydrogen mālama wela e hoʻokō i ka hāʻawi wikiwiki ʻana i nā kauoha hana nui.

Mīkini:ʻO ka mea o Zhaolixin ua hana i ka mālama wela piha, a laila hana ʻia i nā ʻano nui i hoʻopili ʻia e ka mīkini hana e like me ka huli ʻana, wili, ʻokiʻoki, wili, a me nā mea ʻē aʻe, a me ka hōʻoia ʻana i ka hoʻonohonoho kūloko o nā mea tungsten a me molybdenum paʻa, ʻaʻohe pilikia. a me ka puka ʻole, hiki ke hoʻokō i nā pono o nā mea kūʻai aku.

Hōʻoia maikaʻi:E hoʻokō ʻia ka nānā ʻana a me ka hoʻokele maikaʻi mai nā mea maka a no kēlā me kēia ʻanuʻu o ka hana ʻana, i mea e hōʻoia mau ai i ka maikaʻi o kēlā me kēia huahana.I ka manawa like, i ka wā e hāʻawi ʻia ai nā huahana i hoʻopau ʻia mai ka hale kūʻai, e hoʻāʻo ʻia ka ʻano, ka nui a me ka hoʻonohonoho kūloko o nā mea.No laila, ʻoi aku ka koʻikoʻi o ke kūpaʻa a me ka kūlike o nā huahana.